Our Products

Our Products Details

Tapping Machine

- Flexible Arm Electric Tapping Machine

- Flexible Arm Electric Drilling Cum Tapping Machine

Drill Bit / End Mill Grinder

- DrIll Bit Sharpner / Grinder

- End Mill Sharpner/ Grinder

Drilling / Tapping Spindle Unit

- Servo Drilling Spindle Unit Head

- Pneumatic Drilling Spindle Unit Head

- Hydraulic Drilling Spindle Unit Head

- Servo Tapping Spindle Unit Head

- Hydraulic Tapping Spindle Unit Head

- Multi Spindle Head Unit

- Boring/Milling Spindle Unit

- CNC Drilling Tapping Machine

Linear Motion Products

- LM Guideways

- Rolled Ball Screw

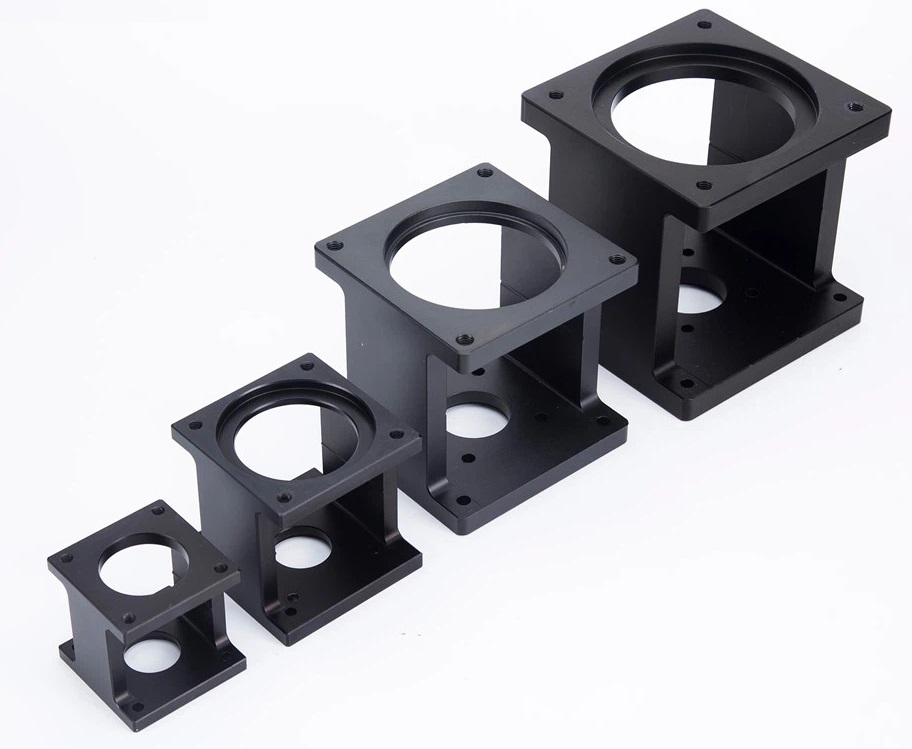

- Motor Mounting Bracket

- Ball Screw End Support Unit

Robot Tool Changer

- Robot Tool Changer

Our Products Brief Details

Flexible Arm Electric Tapping Machine

Flexible Arm Tapping is a versatile and efficient machine designed for precise thread tapping operations in various materials.

- The machine adopts servo drive control, with intelligent torque protection.

- The high-definition screen is simple and flexible.

- Stepless speed change for Manual, Automatic and Vibration mode.

- Automatic mode can effectively control the depth of tapping.

- With Universal movement of head, tapping can be done efficiently in any direction.

Basic Configuration

SMT-16

SMT-24

SMT-36

SMT-48

Tapping Capacity

M3-M16

M6-M24

M6-M36

M6-M48

Working Area

1100mm

1200mm

1200mm

1200mm

Supply Voltage Power

600W/220V

1200W/220V

1200W/220V

1500W/220V

Spindle RPM

0-312

0-200

0-150

0-150

COLLET’S INCLUDED:

SMT- 16: M3, M4, M5, M6-8, M10, M12, M14, M16

SMT- 24 : M6-8, M10, M12, M14, M16, M18-20, M22, M24

SMT- 36: M6-8, M10, M12, M14, M16, M18-20, M22, M24, M27-30, M33, M36

SMT- 48: M6-8, M10, M12, M14, M16, M18-20, M22, M24, M27-30, M33, M36,M38,M42,M48

Flexible Arm Electric Drilling Cum Tapping Machine

• The electric servo cantilever machine is suitable for drilling and tapping various machines, moulds and auto parts.

• This integrated drilling and tapping machine is equipped with an innovative system developed with an articulated swing arm and magnetic chuck lifting rod, which makes it stay perpendicular to the workpiece and ensure the smoothness of up/down sliding.

• With an intelligent touch-screen operator interface, easy and intuitive, you can perform drilling and tapping, to set quota without the need of manually tracking.

• Torque control features help prevent damage to the tap and the workpiece by regulating the amount of force applied during the tapping process.

• This machine adopts cantilever drilling and tapping integration, which is fast and convenient for replacing the existing drilling and tapping products in the market.

• The whole machine adopts the suspended manipulator mode, which realizes the integrated interchange of drilling and tapping, which is flexible and convenient.

Basic Configuration | SFN-1000 | SFN-1200 |

Drilling Capacity | 1-12mm | 6-20mm |

Tapping Capacity | M3-M12 | M6-M20 |

Working Area | 1100mm | 1200mm |

Supply Voltage Power | 600W/220V | 1200W/220V |

Spindle RPM | 1000 | 625 |

COLLET’S INCLUDED:

SMT- 12: M3, M4, M5, M6-8, M10, M12,

Drill Chuck

Drill Bit Sharpening / Grinding Machine

Grinding is accurate and rapid, easy operation with no skill to grind. Economical price that greatly reduces the cost and improves the use effect it can be equipped directly with an accurate angle and long service life.

Benefits

1. Cost Savings

2. Precision Grinding

3. Extended Tool Life

4. Customization

Model | Drill Capacity | Point Angle | Power |

SDG-13 | 3-13mm | 90-135 Degree | AC-220V/120W |

SDG-20 | 3-20mm | 90-135 Degree | AC-220V/120W |

SDG-30 | 3-30mm | 80-140 Degree | AC-220V/250W |

COLLET’S INCLUDED:

- SDG-13 : 11 Collets

- SDG-20 : 18 Collets

- SDG-30 : 28 Collets

Standard Accessories

- ISO Collets

- Wheel (For HSS)

End Mill Cutter Sharpening / Grinding Machine

End mill grinder still use a simple type of operation design, without any grinding experience can also quickly work, whether you are small and medium enterprises, family workshops, personal repair, all can achieve satisfy grinding result Benefits |

Model | End Mill Capacity | Point Angle | Power |

SEM-13 | 4-13mm | 0-5 Degree | AC-220V/180W |

SEM-30 | 13-30mm | 0-5 Degree | AC-220V/250W |

End Mill Cutter Sharpening / Grinding Machine

COLLET’S INCLUDED:

- SEM-13 : 6 Collets

- SEM-30 : 9 Collets

Standard Accessories

- ISO Collets

- Wheel for Carbide

Cam Indexer Drive

Cam Indexing Drives are also called Globoidal Cam Indexers, Cam Indexing Table, Cam Driven Indexer, Fixed Station Indexers, etc. It is a kind of rotary precision transmission component for various automatic devices, which is suitable for a wide range of applications for industries, such as Food and Packing, Pharmaceutical Industry, Aerospace and Defense, Automotive, Electronics, etc.

The cams inside the indexing table are designed to match the precision indexing and idle times without stopping the motor, but can also be used for start-stop applications. These are versatile units suitable for a wide range of rotary driving applications.

Rotary Indexer Drive

Hollow Rotary Table is also called Hollow Rotary Actuator which can be equipped with stepper motor or servo motor. With the most featured central hollow structure and its precision control, Hollow Rotary Table becomes one of the popular rotary components in Automation Industry. Sango Automation provides multiple options of rotary tables, from ouput surface size 62, 85, 130, 200 to 280, as well as reinforced, heavy duty version to maximum meet the requirement for different industrial application. On motor connection direction, we provide side connection and right angle type connection method, which gives more flexibility and space for automation engineers and designers

Harmonic Drive

Harmonic gearboxes, also known as strain wave gear drives, are renowned for their high precision, high reduction ratios, and compact design. Their working principle is based on the interaction of flexible gears and wave generators, achieving efficient transmission and extremely high positioning accuracy.

High Precision and High Reduction Ratios: Harmonic gearboxes have extremely high reduction ratios, typically ranging from 30:1 to 320:1. This high reduction ratio is particularly important in medical devices requiring high precision control, such as surgical robots and imaging equipment.

Compact Design: The design of harmonic gearboxes is very compact, providing high-performance transmission in limited spaces. This is crucial for the design of space-constrained medical devices, such as minimally invasive surgical tools and portable diagnostic equipment

Zero Backlash: Harmonic gearboxes have almost no backlash, ensuring smooth and accurate operation during the device’s process. This is particularly important in medical applications requiring precise positioning, such as mechanical arms and precision scanners.

Drilling / Tapping head Spindle Unit

Drilling Tapping Spindle Head Unit

- High precision, spindle jitter 0.01mm

- High speed, the maximum speed of 7500r/min

- Small size, light weight, suitable for installation

- The use of 0.37kw or 0.75kw motor, suitable for small hole processing.

Multi Spindle HEAD Unit

Square Multi Spindle Head -Adjustable

- The structure of square adjustable multi-axle joint is the same as that of circular one. If the working hole spacing is linear or rectangular, the joint life will not be damaged by too much displacement. The method of use is the same as that of circle.

- According to the product drawings and the hole distance coordinates of the work, the structure of the gearbox is designed to determine the boring position

Square Multi Spindle Head -Fixed

- The structure of square fixed multi-axle joint is the same as that of circular one. The method of use is the same

as that of circle. - According to the product drawings and the hole distance coordinates of the work, the structure of the gearbox is

designed to determine the boring position.

CNC DRILLING CUM TAPPING MACHINE

Drilling Tapping Connecting Machine

- One drilling and one tapping, one-piece machine, suitable for LED lighting industry or multi holes products.

● Can be equipped with multi-spindles head to complete one-time multi holes drilling and tapping operation.

● One person can operate two machines, saving labour and improving efficiency.Model

CN18

CN23

Drilling/tapping ability

16mm/M6

20mm/M20

The spindle taper

B16

MT2

Maximum spindle stroke

100mm

120mm

Spindle speed

CVT 100-2500rpm

CVT 100-2500rpm

Distance between spindle end

650mm

600mm

Spindle motor power

130-2.0KW Servo motor

130-2.6KW Servo motor

Z-axis feed motor power (servo)

0.75KW

1KW

The spindle diameter

60mm

70mm

Control system

PLC and touch screen

PLC and touch screen

Feed way

Ball screw

Ball screw

Weight

250kg/175kg

400kg/300kg

Volume

880*610*1000mm

1000*700*1400mm

LINEAR MOTION PRODUCTS

LM Guideways: Linear guide rail movement is used to support and guide the moving parts, according to the given direction of the reciprocating linear movement. Specially Hard Chrome Plated Can increase the hardness and durability of the surface, prevent corrosion and even make it easier to clean

Precision Ball Screw :

Ball screws are efficient part, which requiring less than 30% of the torque. So, Straight line motion can be easily transformed into rotary motion. They maintain smooth motion characteristics even when preloaded.

Ball Screw End Supports: Ball Screw Support is an important supporting part of the ball screw, used to fix the screw and avoid vibration and displacement and BF refer to types of ball screw end supports, while “blackodising” is a surface finishing process that creates a black oxide coating.

LM Rail Manual clamps: Manual Clamp are clamping devices, used to secure parts, especially in linear motion applications like LM guide rails. They are designed for easy operation with a lever or turn, allowing for quick clamping and unclamping without the need for additional tools. These clamps are a common choice for securing various parts, including Z-axes or machining tables, ensuring they remain in a fixed position.

Servo & Stepper Motor Mounting Bracket: Motor and screw connection has an upgrade mode, now there is a new version of motor drive seat, servo motor mounting bracket for you to solve the problem of concentricity of motor and screw connection, the traditional one by one connection mode is changed to integration, higher accuracy, easier installation.

ROBOT TOOL CHANGER

A robot tool changer is a device that enables robots to quickly switch between different end effectors or tools, increasing flexibility and efficiency in automated processes. It consists of a robot-side and a tool-side, facilitating the automatic exchange of tools within seconds.